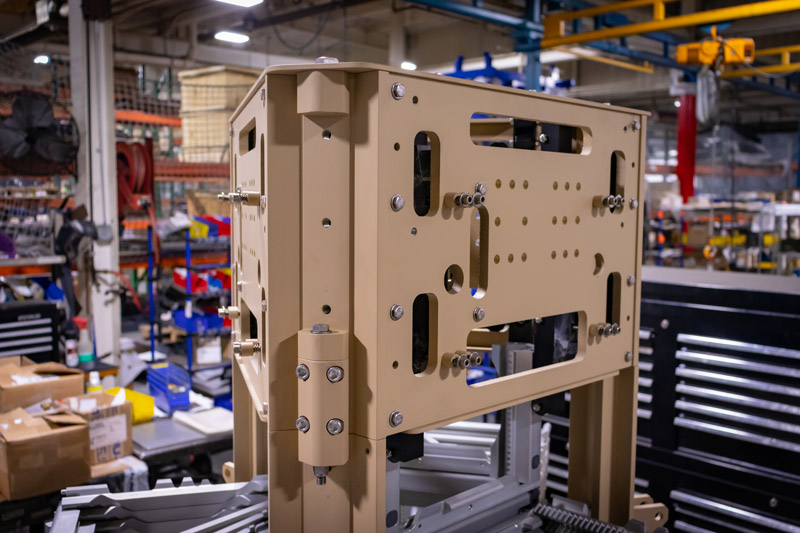

In today’s competitive market, OEMs need full-service contract manufacturing partners that simplify procurement, reduce lead times, and ensure quality at every step of a project. They want turnkey manufacturing solutions that integrate all aspects of manufacturing from engineering support, precision machining, and metal fabrication to assembly and supply chain management – all from the same manufacturing partner. Lou-Rich is that partner.

Often, OEMs find that the purchase of expensive equipment for only a few parts isn’t feasible and will look to contract manufacturers with such equipment. Lou-Rich, on the other hand, maintains high machine utilization rates that justify investments in the latest processing technologies and, in turn, make them available to their customers. Lou-Rich also eliminates the need for all the associated staff and infrastructure an OEM would need to support the equipment – software updates, personnel requirements, etc. – they purchased.

Better Parts Produced Cost-Effectively

When helping OEMs produce existing parts more cost-effectively, contract manufacturers will conduct design for manufacturability studies where they evaluate an OEM’s part and determine better ways to produce it. The resulting part will function the same way the old version did but will cost less.

Lou-Rich’s highly skilled engineering and design staff often receive part designs from OEMs that are unnecessarily difficult to manufacture that drive higher costs. In these cases, their engineers develop cost-effective options and/or workarounds for the OEM yet maintain the part’s originally engineered functionality while reducing labor, material, and time for the job.

More Than a Manufacturing Partner

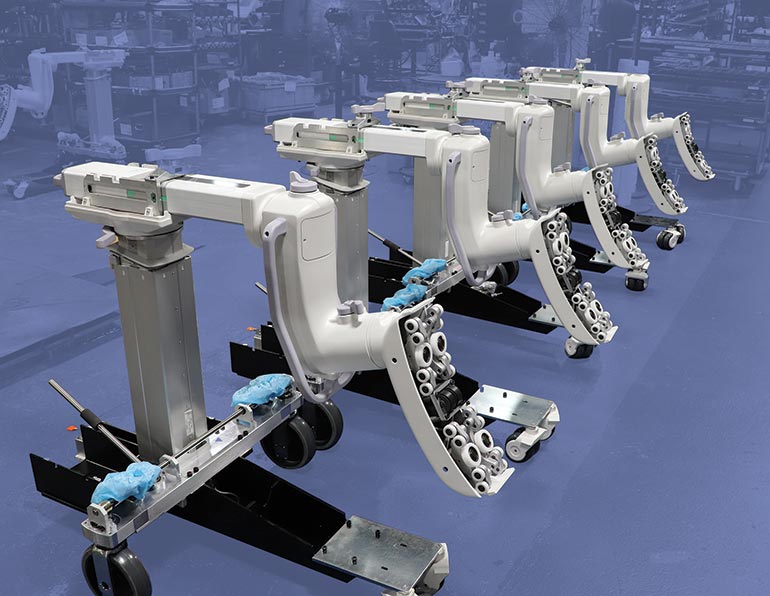

Successful project results depend on contract manufacturers operating seamlessly as just another department within an OEM’s manufacturing operations through streamlined communication and manufacturing flexibility. Lou-Rich gets involved at the onset of a project, starting from the design and concept stage to provide manufacturing input through the project. Ongoing communication eliminates the need for design changes/multiple iterations down the road that result from insufficient communication as well as non-manufacturability issues that should have been resolved in the project’s early stages.

Besides having the technical capabilities and production capacity to do a full-service job, end-to-end contract manufacturers like Lou-Rich also provide project management. No matter how large and/or complex a project is, their engineering and design team work closely with the company’s customer service and the production departments to ensure every project goes smoothly.

To always provide their customers with cost-effective solutions, Lou-Rich evaluates jobs based on the added value its services bring to the table. Certain jobs that require multiple processes at Lou-Rich – such as laser cutting, press brake, welding, and assembly – offer the best benefits and value to customers.

At Lou-Rich, it’s all about the customer experience and providing solutions to their problems, and every department plays a role. Whether it’s the company’s engineering department figuring out how to produce a part no one else could or the materials manager ensuring raw materials are cost-effective and ready when needed, Lou-Rich is a full turnkey manufacturing partner with the expert team and advanced technology to get the job done.

Partner with a Team That’s Built for Your Success

Whether you’re looking to improve manufacturability, reduce costs, or streamline your supply chain, Lou-Rich is ready to help. Let’s talk about how our turnkey solutions and engineering expertise can support your next project.

Contact Us Today to start the conversation.