Design for Manufacturability (DFM) is a game-changer in product development, reducing costs and improving production efficiency. At Lou-Rich, our engineering experts collaborate closely with customers to refine part designs and ensure high-quality, manufacturable solutions.

Our highly experienced engineering team has decades upon decades of in-house manufacturing experience. Lou-Rich’s CNC Programming Engineer Adam Quimby, for instance, has been with us for 18 years, while our Senior Manufacturing Engineer Jason Gordon is in his 26th year with us, and that’s just two examples of our team. This vast experience differentiates us from our competitors and is why customers come to us.

Developing a Tolerance for Production

While our customers are knowledgeable and experienced in terms of their industries, they rarely have the full manufacturing background or experience needed for the finer details that drive cost. For instance, they are often unaware of the exact tolerances achievable with various part production processes. They have a general understanding of what a piece of equipment will do, but not of the tolerances those processes will hold in a production environment.

With there being so many variables for tolerancing, Lou-Rich can assist customers and give suggestions that will yield better results.

DFM From the Ground Up

When you come to us with a project, we get involved at the design stage so that we can help eliminate many of the headaches associated with changes and multiple part iterations. We analyze a project internally and evaluate the operations involved to determine the best way to process a part and meet the customer’s expectations.

Most customers come to us in their prototype stage and with a target cost-per-part amount. With that target price, we’ll put a team together for general discussions and do some research on what is needed to get to that price point. In fact, target per-part pricing makes projects easier on our end.

In terms of DFM, we’ll look at the part in general and first determine if it should be a casting, weldment or machined from raw material. We then make processing recommendations based the initial concept or on the existing design and follow up those recommendations with pros and cons along with cost estimates to support them.

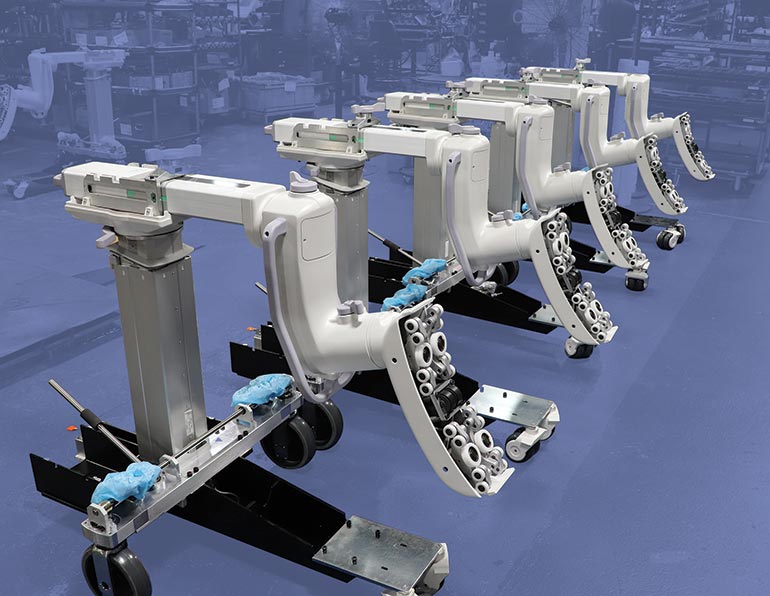

For example, customers often come to us with weld assemblies involving multiple components. In those instances, we have the experience to easily determine if they can instead reduce costs with a single casting that combines all those assembled components.

Why Come to Us

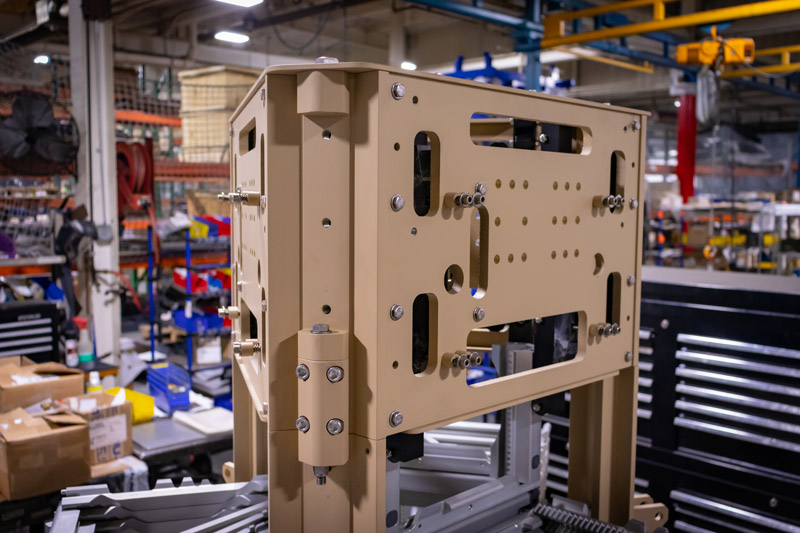

Lou-Rich offers a lot of quality improvement for high-level parts. Most of the parts we do are complex, and few – if any – of our competitors are able to handle such projects. We reduce production process cycle times as well as costs for customers.

Often times, our customers trust us so much so that after a project, they’ll turn the full production over to us, and in many instances, we’ll meet customer year-over-year cost reduction targets. To do so, we submit change ideas and suggestions as to how they could alter their parts or processes to reduce costs.

We continuously add new processing capabilities at Lou-Rich. When we’re asked to run production, we’ll invest in the necessary equipment if our current machine capacity dictates that we need to do so.

Learn how our DFM expertise leads to better performance, lower costs, and faster production timelines by connecting with our team today: https://lou-rich.com/contact/