Since opening our doors in 1972, Lou-Rich has grown into one of the Midwest’s most trusted contract manufacturers for complex, high-precision projects. But behind the company’s machining centers, fabrication equipment, welding cells, and complex assemblies is its greatest asset: the people who own it.

As a 100% employee-owned company since 2012, Lou-Rich empowers our team to take ownership in driving innovation, accountability, and customer satisfaction.

Here’s how our employee-owners make the difference.

Empowered to Succeed

Being an employee-owner at Lou-Rich means more than receiving a share of the profits. It means being decision-makers when it comes to shaping our company’s future. Everyone, from welders to engineers, has a personal stake in Lou-Rich’s success. The ownership mindset creates a culture of accountability, collaboration, and pride. Employee-led teams are empowered to solve challenges, identify improvements, and bring ideas forward, knowing their input matters.

For example, our structured “I² Training” helps employees develop leadership skills that support Lou-Rich’s performance-driven environment. It focuses on building core leadership competencies such as communication, accountability, coaching, conflict resolution, and team motivation. From the shop floor to the front office, our people are encouraged to lead, grow, and contribute to excellence.

Hone Manufacturing Skills and Knowledge

We believe that developing talent from within is the key to long-term success. From the start, new hires are paired with department mentors who provide onboarding support and daily guidance. Many of our employees began their careers at Lou-Rich on the shop floor and now lead departments and teams. Through mentoring, hands-on experience, and leadership development programs, we invest in our employee-owners’ career advancement and skillset growth.

Along the same lines, we extend training to people outside our building. We partner with local workforce development programs like Youth Skills Training to introduce high school students to real-world manufacturing careers. Our commitment to the next generation allows us to put the best mentorship practices to work on a regular basis. In addition, the program supports our recruitment, ensures knowledge transfer, and sets us up for long-term success.

Deliver a Seamless Customer Experience

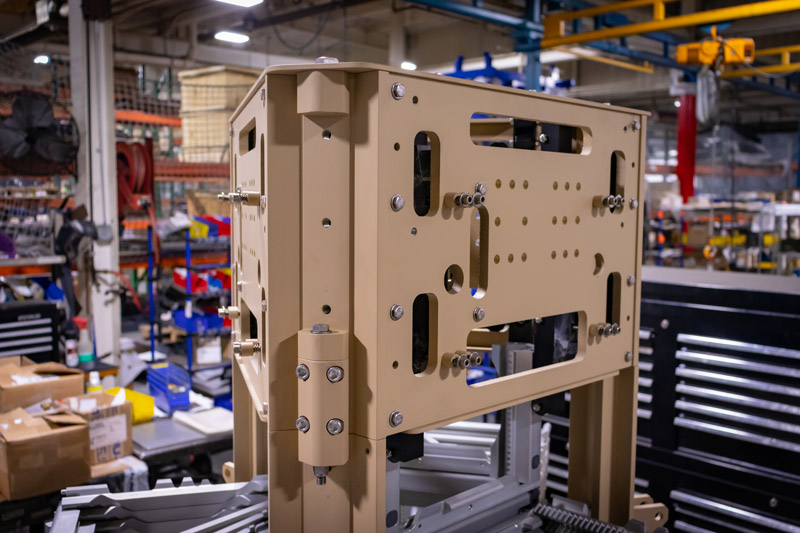

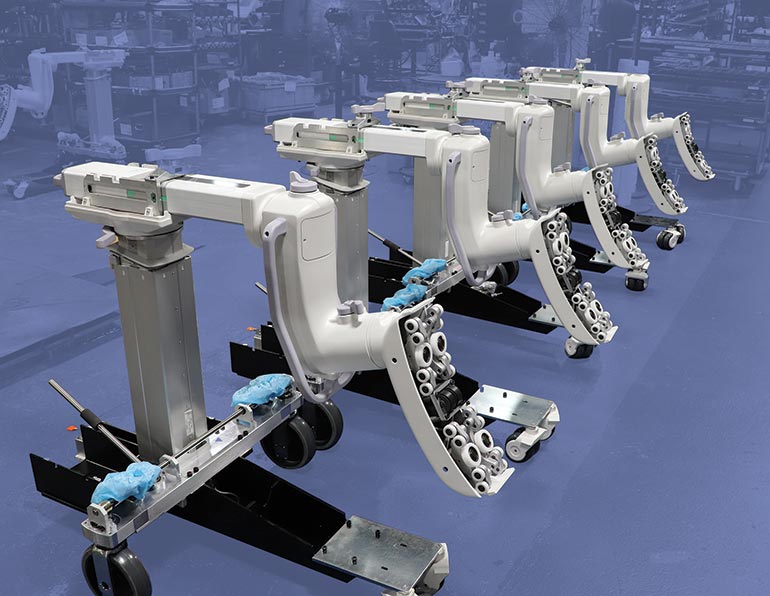

You rely on Lou-Rich to manage complex manufacturing challenges from prototyping through final assembly. Our fully integrated capabilities – precision machining, metal fabrication, welding, paint, and assembly – are all under one roof, meaning we bring you streamlined workflows and reduced lead times.

Lou-Rich employee-owners understand how their work fits into your expectations, which fuels greater attention to detail, better communication across departments, and a more responsive approach to each individual customer’s needs. When every team member sees themselves as a stakeholder, they’re naturally more committed to delivering a smooth, high-quality experience.

Offer Expert Design for Manufacturability (DFM) to Optimize Production

Our team’s technical experience plays a key role in helping customers refine product designs for cost-effective, high-quality manufacturing.

As employee-owners, we prioritize collaboration early in the development process to identify opportunities for simplification, material optimization, and more efficient assembly. Because our engineering, sourcing, and production teams work closely and with equal accountability, customers benefit from practical solutions that balance performance with manufacturability from day one.

Embed Quality into Every Step of the Process

At Lou-Rich, quality is built into every step of the process. Employee-owners take personal pride in getting it right the first time, and company-wide quality metrics are tied to performance-based rewards. Monthly cash incentives and team recognition help reinforce a culture where precision and consistency matter.

Our systems are designed to uphold the highest standards, and our people commit to achieving them. Because when employees are also owners, quality becomes more than a goal. It becomes second nature.