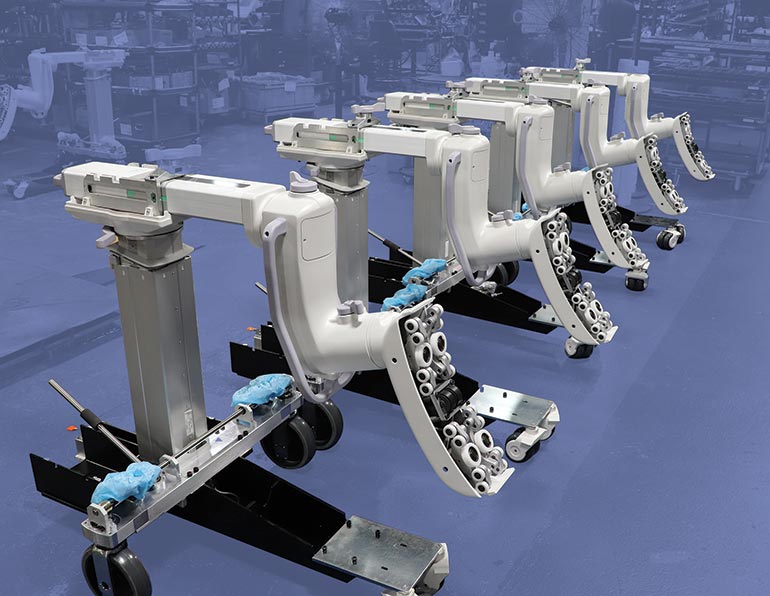

In the medical technology (MedTech) sector, manufacturing calls for extreme precision and control with numerous quality requirements. For Lou-Rich MedTech customers, we pride ourselves on meeting all design and testing requirements to provide them with peace of mind, and our built-in procedures ensure all components are assembled properly and product safety is held to the utmost standards.

The main reason MedTech Original Equipment Manufacturers (OEM) turn to us with their complex parts and assemblies is because we deliver with greater precision, speed, and cost efficiency. Discover how we make it happen in this blog, from development to the final product.

Your MedTech manufacturing partner

Medical technology innovators need to focus their energy on advancing product design and improving patient outcomes — not on the complexities of manufacturing. That’s where Lou-Rich comes in.

Our team partners with customers early in the development process to translate design intent into manufacturable reality. We advise on critical production factors such as machining tolerances, achievable geometric dimensioning and tolerancing (GD&T), optimal CNC cutting approaches, and practical feature design for manufacturability.

This design-for-manufacturing (DFM) expertise is what sets Lou-Rich apart. By collaborating from concept through production, we help medical OEMs achieve their desired part outcomes through proven processes that ensure consistency, accuracy, and repeatability — from prototype to full-scale production.

Lou-Rich for MedTech manufacturing wellness

As part of our design-for-manufacturability technique, we get involved early in the part production process, which allows us to reduce costs on the front end of the supply chain. For our customers, we balance speed and cost effectiveness without ever sacrificing precision or quality.

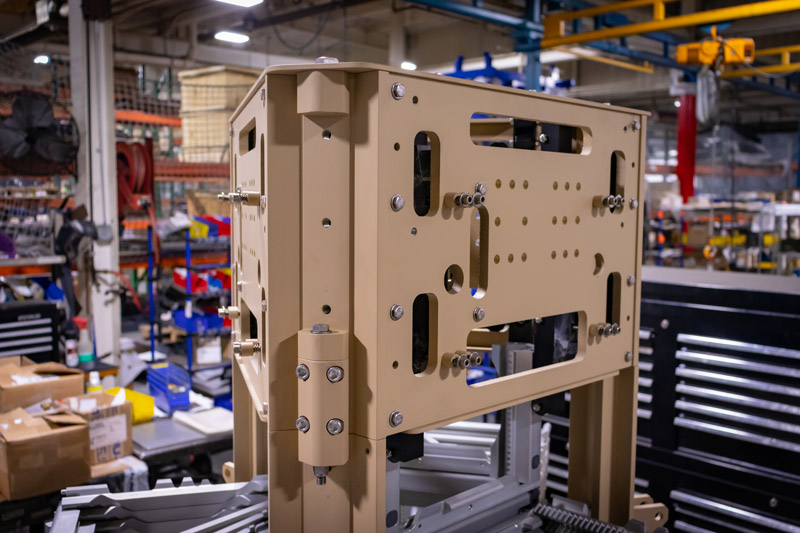

Our team of expert machine programmers and manufacturing engineers work together with our tool design and build department to develop strong and reliable machine fixtures. Our CNC programming staff will then optimize machining speeds and feeds matched to the part application and process. With our quality systems, our entire team validates that we’re achieving our cost-effectiveness, efficiency and throughput goals while meeting customer requirements.

What our MedTech customers value most when working with us is our culture of employee owners who are very in-tune with our processes and who have extensive manufacturing knowledge. Customers are familiar with our team and appreciate the fact that they work with the same people regularly.

For new customers, a Lou-Rich program manager oversees the account along with at least one project engineer assigned to that customer. A quality engineer and a customer service representative are also assigned to the customer’s specific account. All these individuals ensure that the process yields the customer’s desired results in terms of quality, pricing and repeatability.

Lou-Rich means MedTech quality and traceability

Many of the MedTech components and assemblies we produce require in-depth traceability as far back in some instances as the torque level used on a fastener. Traceability requirements vary widely, and we accommodate each customer’s requirements.

For traceability, we use our enterprise resource planning (ERP) system to generate a serial number for each piece. Those serial numbers get incorporated into the part label and are laser-marked or dot peened onto the parts. Then, we trace the serialized units back to the production paperwork and checklists if needed.

When a customer requires traceability of materials, we rely on various processes to collect information from raw materials and each operation through to the final product. We then summarize that information along with any certificates based on Shop Orders and Purchase Order (PO) numbers.

We conduct several quality checks throughout our production process. Those include Receiving Inspections, First Article Inspections, First Piece Inspections, In-process Inspections and Final Inspections. We also rely on Control Plans, Frequency of Inspection sheets and checklists to identify how often individual items are inspected.

We have over 4,500 gauges in our calibration system, along with manual and programmed CMMs for checking parts. Additionally, our team carries out many visual inspections during MedTech manufacturing operations.

To further standardize production, we’ve implemented many kitting carts and shadow boards. And we inspect these carts before and after use to ensure all parts are included in a customer’s High Level Assembly (HLA). Finally, performance testing confirms if the part performs as expected before it is shipped to the customer.

MedTech trends shaping customer projects include opportunities for American-made or American-manufactured products. While many MedTech devices are produced overseas, OEMs are moving more manufacturing to state-side production and sourcing to US suppliers like Lou-Rich for machining, fabricating, high-level assembly and other processes. When they do, we help them tailor their part designs to required production processes, guaranteeing they achieve the required yield and perfectly machined parts that meet their needs.