At Lou-Rich, lean manufacturing is more than a buzzword. It’s a proven foundational principle of how we maintain efficiency and quality simultaneously throughout our shop. From reducing lead times to optimizing labor and inventory, lean principles ensure we’re more than just meeting customer expectations – we’re exceeding them.

In this blog, learn how we as a company put lean manufacturing to work in providing our customers with the high-quality production we’re known for, all at a fraction of the cost of labor requirements and material waste.

Overcome Bottlenecks to Maintain Balance

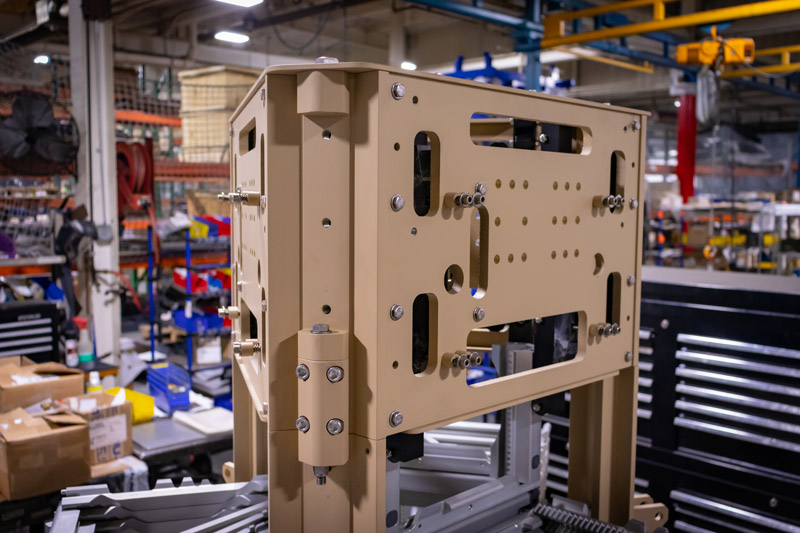

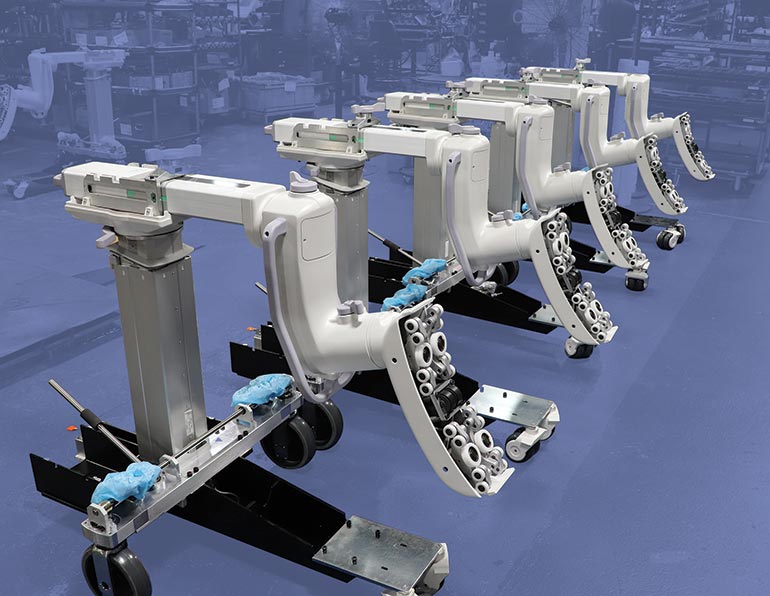

When Lou-Rich first started building high-level assemblies for MedTech, we worked through various trials to achieve the results we needed. At first there was much waste built into our process; batch building causing over production and hiding defects, unbalanced assembly lines causing waiting, had too much inventory of one part and not enough of another, and wasted motion looking for tools/parts. This created bottlenecks and delays in the upstream processes.

With the application of lean practices, we reimagined the entire operation. We moved to a single-piece flow system and performed detailed time studies to help us determine the right number of operators on the line using work balance charts. By changing the number of operators, we can modify our cycle time to ensure it remains less than or equal to the takt time, which is set by customer demand. Every station was sized to fit each specific task, ensuring each team member could contribute efficiently without overburdening any one part of the process. Problem-solving with lean manufacturing resulted in smoother production flow, improved throughput, reduced labor and overall shorter lead times.

While we focus heavily on efficiency in our assembly process, our lean manufacturing principles flow throughout each manufacturing process at Lou-Rich – from machining to welding to laser cutting and more – and ensures that every step we take adds value, minimizes waste and keeps production moving seamlessly throughout each station.

Lean Principles Go Beyond the Production Line

One of the key lean manufacturing tools we’ve implemented is a two-bin system used to control how and when parts are replenished. When one bin is empty, it signals upstream operations to produce more, which prevents overproduction and keeps our inventory as lean as possible.

We also took our lean practices a step further through the use of our Enterprise Resource Planning (ERP) software. Now, when an assembler completes a unit, the software automatically deducts the parts from inventory and triggers a replenishment order based on real-time usage. This automation reduces manual tracking and ensures we only produce what we need, when we need it. For our customers, this means faster response times, consistent product availability, improved order accuracy and overall lower costs by avoiding overproduction.

Built-in Efficiency Benefits Everyone

Not only does our overall production benefit from lean manufacturing, but so do our customers. By implementing a pull-based manufacturing system as opposed to a purchase order-driven system, our customers – many of whom are OEM manufacturers – have gained more flexibility to request different models with less hassle, fewer open orders and reduced management overhead.

For Lou-Rich, lean manufacturing doesn’t mean squeezing more work out of fewer operators. It’s about building a production system that’s smart, scalable and resilient. As a result, we’ve been able to streamline labor requirements, inventory costs and machine bottlenecks, all while maintaining high-quality production, responsiveness and on-time delivery.

As we continue to improve and adapt, lean manufacturing remains one of our prime principles. It allows us to stay competitive, build trust with our customers and provide them repeatable, high-quality results that are scalable and reliable.