Machining Solutions

At Lou-Rich, precision machining is a core strength. With nearly 50 machining centers, we have the capability to meet even the most demanding customer projects. From simple turned parts to large, complex multi-axis machining, we deliver precision and efficiency.

Lou-Rich: Your Machining Solutions Partner

- Experienced Employee-Owners – Skilled machinists dedicated to precision and efficiency.

- Advanced Capabilities – Handling a variety of machining projects, from simple to highly complex.

- End-to-End Solutions – Engineering support, precision machining, and quality assurance.

Whether you need precision-formed components or large welded assemblies, we have the expertise and technology to bring your project to life. View our technical capabilities ›

Our Machining Capabilities

Lou-Rich’s machining capabilities span a wide range of applications, ensuring high-quality, efficient production for any project. Many of our operators have decades of experience, and our customers return because of our unrelenting commitment to quality.

Horizontal Machining

For high-efficiency and large-scale production, our horizontal machining centers provide flexibility, precision, and speed. These systems are ideal for multi-sided machining, maximizing throughput while maintaining tight tolerances.

- 15+ Horizontal CNC Machining Centers 400MM-1250MM

- 4 Flexible Machining Centers (FMC) for quick change, nimble production; 400MM, 500MM, 630MM. From 20 pallets to 34 pallets.

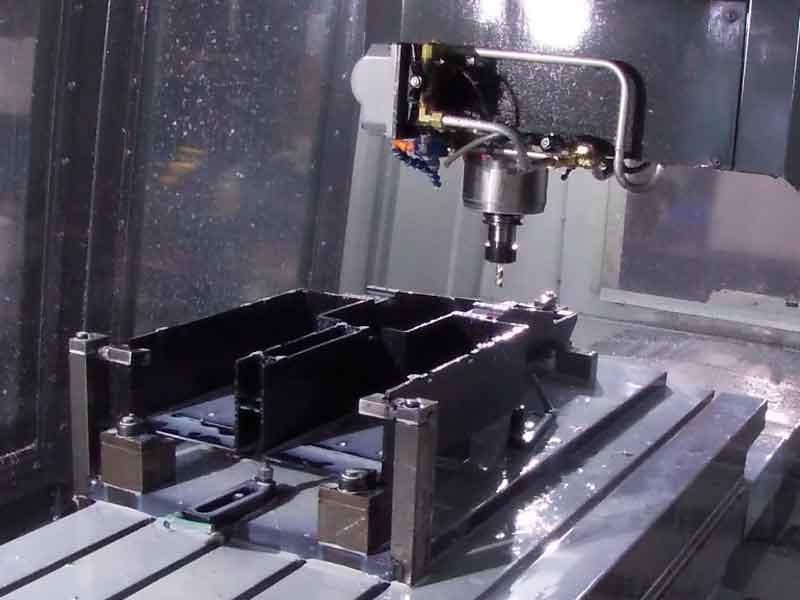

Vertical Machining

Our vertical machining centers deliver precision and adaptability for projects requiring intricate detailing or complex geometries. With multi-axis capabilities and robotic handling, we can produce high-quality components at scale.

- 5 Axis Drill Tap Mill(1): up to 16” x 24

- 23 Vertical Mills: up to travels of 84 X 40 X 31 4th axis capable

- 5 Axis 500MM mill robot tended

- Multiple machines with automated pallet changers

- Vertical machining capabilities from 3-axis to 5-axis

Turning Equipment

Our turning solutions allow for high-precision and efficient production of cylindrical components. Whether for small or large-scale production, our turning equipment delivers consistency and accuracy with every part.

- VTL 36.22” max OD 31.49 max length of part

- Swiss Lathe (4): 12 foot bar feeders up to Ø52MM

- 4 Axis Lathe (3) Twin turret machines

- 5 Axis Lathe (4): Ø10.5”/Ø3.1” Bar with live tooling

- 3 Axis Lathe (5): Ø17.7”/Ø3” Bar

- Mazak Multiplex – dual main spindle lathe, with live tooling, Y-axis and gantry loader: Ø16.9”

- Mazak Multiplex – dual spindle lathe, with slug loader: Ø16.9” Swing and vacuum extract

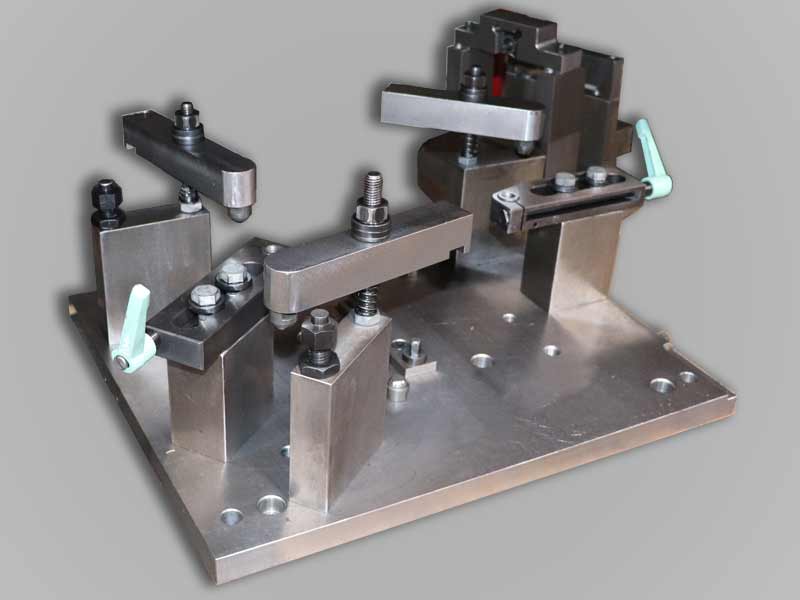

Fixture Design and Build

Ensuring stability and accuracy during machining, welding, and assembly, our in-house fixture design and build capabilities help optimize production processes and maintain part consistency.

- In-house design and manufacturing of custom fixtures to support precision machining

Technical Support

At Lou-Rich, we invest in cutting-edge technology and a skilled support team to maintain peak efficiency. Our experts ensure seamless operations with advanced programming, maintenance, and mistake-proofing techniques.

- Dedicated programming and maintenance staff to maximize uptime

- Latest in CAD software, tooling, and technology for optimized performance

- Mistake-proofing programs to ensure quality on every part

Quality Is in Our DNA

Our commitment to quality is embedded in every step of the assembly process. With a dedicated 35,000-square-foot assembly facility, ISO 9001:2015-certified processes, and precision tools—including custom and pneumatic solutions—we guarantee precision and reliability in every assembled product. Discover our quality standards ›