Engineering & Complex Manufacturing

Backed by decades of experience, Lou-Rich has grown from a 1972 tool & die shop into a go-to partner for complex manufacturing. Our 20+ skilled engineers and technical staff work hand-in-hand across departments to turn challenging ideas into manufacturable solutions—guiding projects from concept to completion and solving the problems others avoid.

Lou-Rich: Your Engineering & Complex Manufacturing Partner

- Engineer-Led Mindset – Team of experienced engineers turning complex ideas into efficient, manufacturable solutions.

- Built for Complexity – We excel at intricate, multi-step builds that others avoid.

- Collaboration from Concept to Production – Partnering with your team from design through full-scale manufacturing.

- End-to-End Support – From DFM and prototyping to production, process development, and continuous improvement.

Have a project that others consider “too complex”? Let’s talk. View our technical capabilities ›

Our Engineering & Complex Manufacturing Capabilities

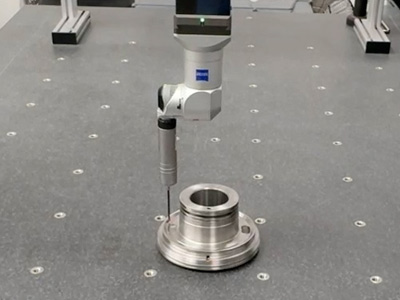

Lou-Rich combines deep technical knowledge and complete engineering services with the tools and processes needed to deliver exceptional outcomes on high-complexity projects. Whether you need precision assemblies, complex geometries, or integrated systems—we’ve got you covered. Our team applies industry best practices, robust project management, and a DFM mindset to deliver manufacturable solutions—on time and on budget.

Design for Manufacturability (DFM)

- Part of every design review, DFM helps identify improvement opportunities early

- Focused on driving out unnecessary costs through better material utilization, shorter lead times, and smarter design

- Proven ability to deliver long-term cost reductions across project lifecycles

Process Control

- ISO 9001:2015 Certified (since 1998) – Quality management system ensuring standardized, documented, and continuously improved processes.

- Engineering Control System – Centralized oversight of product design, specifications, and change management.

- Lean Manufacturing Practices – Waste reduction, efficiency optimization, and continuous improvement methods applied throughout production.

- Process Mapping – Clear visual workflows to standardize operations, identify bottlenecks, and ensure process consistency.

- Detailed Work Instructions – Step-by-step documentation ensuring repeatability, compliance, and quality assurance.

- ERP-Integrated Control – System tracks revision control, detailed Bills of Material (BOM), and routings for accurate production planning and traceability.

Manufacturing Process Development

Built on proven methods and collaboration, our process development ensures every part is made with efficiency, quality, and repeatability in mind. We design smart systems that support long-term success.

- Methodical approach to documenting and implementing efficient processes

- Best practices applied across all stages of the product lifecycle

- Engineering collaborates closely with production to drive continuous improvement

- Design for Manufacturability embedded in every step to improve quality, reduce cost, and shorten timelines

Project Management & In-House Expertise

From the first meeting to final delivery, our project management approach ensures your vision stays on track. We provide structure, accountability, and a single point of contact throughout every phase.

- Clear project charters define scope, milestones, resources, and team roles

- Scheduled status reports to ensure alignment and on-time performance

- A single point of contact for efficient and transparent communication

- Every complex job is assigned one of our dedicated Quality Technicians

- On-site Stratasys 3D FDM printer enables rapid prototyping and quick-turn parts

- In-house fixture design and build enhances precision and eliminates outsourcing delays

Problem-Solving in Action – Tower Solutions Case Study

Complex manufacturing often starts with complex challenges. Our work with Tower Solutions is a powerful example of how Lou-Rich applies engineering expertise and DFM principles to build better, smarter, and stronger.

Project Highlights:

- DFM-Driven Redesign – Collaborated early to enhance strength, reduce weight, and simplify fabrication.

- Seamless Production Integration – Handled everything from cutting and forming to welding and painting.

- Assembly-Ready Output – Delivered completed parts to Tower’s assembly site, ready for installation.

Quality Is in Our DNA

Our commitment to quality is embedded in every step of the assembly process. With a dedicated 35,000-square-foot assembly facility, ISO 9001:2015-certified processes, and precision tools—including custom and pneumatic solutions—we guarantee precision and reliability in every assembled product. Discover our quality standards ›