Fabrication & Welding

At Lou-Rich, precision metal fabrication and welding are at the heart of our manufacturing expertise. With over 50 years of experience, we specialize in delivering custom and complex metal fabrication solutions tailored to meet the high expectations of our customers.

Lou-Rich: Your Fabrication & Welding Partner

- Experienced Employee-Owners – Skilled craftsmen ensuring precision in every project

- Diverse Capabilities – Handling light-gauge sheet metal to heavy plate stainless steel, and everything in between

- End-to-End Solutions – From prototyping to full-scale production

Whether you need precision-formed components or large welded assemblies, we have the expertise and technology to bring your project to life. View our technical capabilities ›

Our Fabrication & Welding Capabilities

Lou-Rich’s advanced fabrication and welding capabilities allow us to handle a wide range of projects, from prototyping to full-scale production. We work with various metals and alloys, ensuring the right solution for each application. Our core capabilities include:

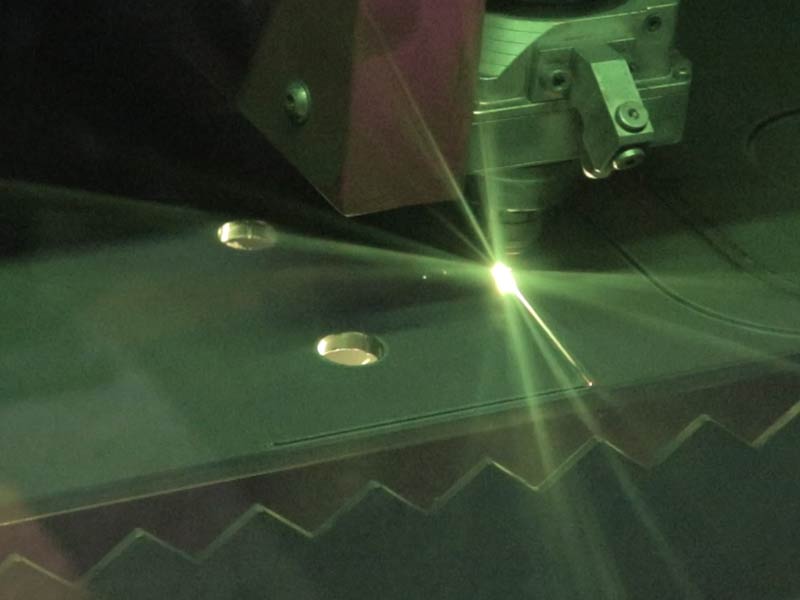

Precision Laser Cutting

Our advanced laser cutting systems provide fast, accurate, and clean cuts, reducing material waste while maintaining tight tolerances. Whether you need high-volume production or custom prototypes, our laser cutting technology ensures efficiency and repeatability.

- 6000 & 10,000-watt Fiber Optic Lasers – Cuts materials up to 1″ thick & integrated with an automated material handling system for quick turns

- 4000-watt Tube Laser – Handles round and square tubing

Metal Forming

From simple bends to complex geometries, our metal forming processes provide reliable, repeatable results. Our high-tonnage presses shape a variety of metals while maintaining strength and dimensional accuracy.

Metal Forming Equipment

- 90-ton & 175-ton Brake Press – Ideal for precision bending of sheet metal, capable of producing complex forms with tight tolerances.

- 60-ton Mechanical Press – Versatile for a range of forming tasks involving small to medium-sized parts

Welding Expertise

We provide high-quality welding solutions, from manual craftsmanship to fully automated robotic welding. Our team follows AWS standards to ensure structural integrity and precision in every weld.

- Manual Welding Stations – AWS-certified MIG, TIG, and Spot Welding

- Robotic Weld Cells (5) – Precision welding for high-volume and repeatable weld placement and bead control

Expertise in Large Weldments – Jarraff Case Study

Manufacturers of industrial equipment need large weldments that are strong, precise, and built to last. At Lou-Rich, we specialize in fabricating and welding heavy-duty structures that withstand demanding environments. A prime example is our partnership with Jarraff Industries Inc., where we leveraged robotic welding technology and our expert fabrication team to deliver high-quality, repeatable large weldments for their land-clearing equipment.

Project Highlights:

- Robotic Welding Precision – Ensured consistent, high-quality welds for structural integrity.

- Heavy-Duty Fabrication – Manufactured large-scale weldments for rugged industrial use.

- Optimized for Production – Scalable solutions to meet Jarraff’s long-term manufacturing needs.

Quality Is in Our DNA

Our commitment to quality is embedded in every step of the assembly process. With a dedicated 35,000-square-foot assembly facility, ISO 9001:2015-certified processes, and precision tools—including custom and pneumatic solutions—we guarantee precision and reliability in every assembled product. Discover our quality standards ›