Tool Design & Fixture Build

From CAD to cutting – we engineer the fixtures that make great manufacturing possible. Precision fixtures designed, built, and proven in-house.

Built on Generational Expertise

Lou-Rich was founded in 1972 by Louie Larson and Richard Ackland – two skilled tool and die machinists with a passion for precision and problem-solving. What began as a tool and die company quickly evolved into a full-service contract manufacturer, but that foundation in tooling still drives everything we do today.

More than 50 years later, tool design and fixture build remains one of our core competencies. It’s not just part of our history – it’s part of our everyday operations.

Our design team has over 40 years of experience in designing fixturing and work holding for a broad range of manufacturing processes.

Our in-house tool room is fully equipped and staffed by a dedicated team of experienced professionals who build production fixtures to the same standards Louie and Richard demanded from the start.

- Fixtures engineered to optimize the manufacturing process, reduce scrap, and streamline setup

- Designed for precision, built for repeatability

- Durable tooling built to last in real-world production environments

Whether we’re supporting our own internal production or helping an OEM improve their process, we apply the same level of craftsmanship and care that’s been part of our DNA since day one.

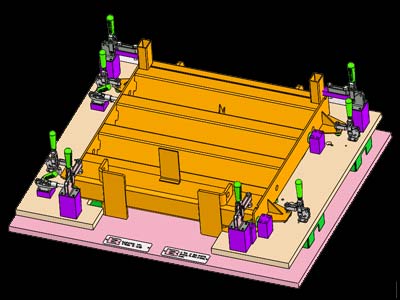

The Fixture Design Process

Ensuring stability and accuracy during machining, our in-house fixture design and build capabilities help optimize production processes and maintain part consistency. See how our in-house process turns concepts into reliable, repeatable tooling.

Step 1 – CAD Design

Our engineering team creates multi-layered CAD models optimized for both functionality and manufacturability.

Step 2 – Fixture Build

We fabricate and machine custom tooling in our fully equipped tool room, ensuring precision and quality at every stage.

Step 3 – In-Use Application

The final fixture goes into the machine, holding the real-world part it was built for – delivering reliable, repeatable results.

In-House Fixture Design Services for OEMs & Manufacturers

Keeping fixture design in-house allows us to deliver quality, consistency, and efficiency at scale.

While our fixture design capabilities support our internal operations, we also offer these services to other manufacturers and OEMs. If you’re building complex parts and need reliable tooling – we can help.

Partnering with Lou-Rich means:

- Shorter lead times by keeping everything in-house

- Cost savings through intelligent, manufacturable designs

- Support from engineers who understand the real-world application

Quality Is in Our DNA

Our commitment to quality is embedded in every step of the assembly process. With a dedicated 35,000-square-foot assembly facility, ISO 9001:2015-certified processes, and precision tools—including custom and pneumatic solutions—we guarantee precision and reliability in every assembled product. Discover our quality standards ›