VERTICAL LATHE MACHINING

Contract Manufacturing. Engineered for Success.

Are you looking for a partner with Vertical Lathe Machine capabilities?

Vertical Lathe Machining

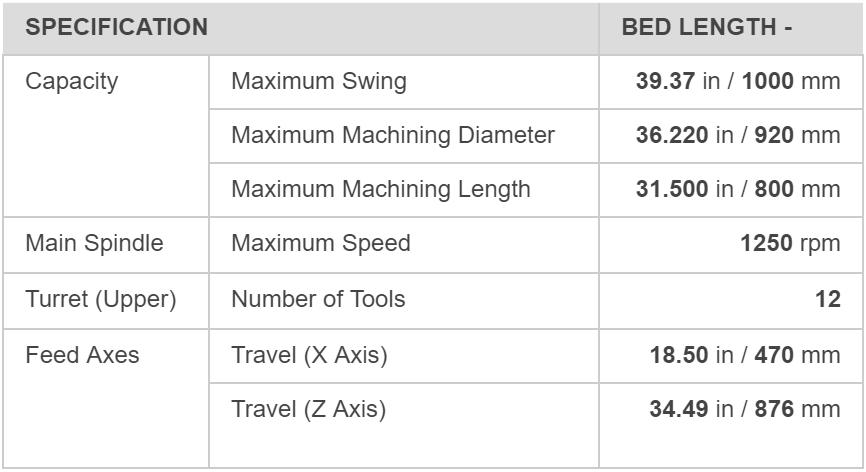

At Lou-Rich, our Vertical Turning Lathe (VTL) service stands as a pinnacle of precision and innovation in the realm of contract manufacturing. Harnessing the power of our 2 Mazak MEGA TURN 900 Vertical Turning Centers, we’re adept at transforming challenging workpieces into high-quality components.

With a keen focus on heavy-duty, intricate machining tasks, our vertical lathe machine service is tailored to meet the unique demands of various industries, from aerospace to construction.

Our team, comprising seasoned professionals, is dedicated to delivering excellence in every project, ensuring our clients benefit from our unwavering commitment to quality and efficiency.

Dive deeper into our capabilities or arrange a visit to experience the Lou-Rich difference firsthand – where your most complex CNC lathe machine challenges find expert solutions.

What’s Vertical Lathe Machining

Vertical Lathe Machining is a type of CNC machining that vertically holds a workpiece while performing various machining operations, such as boring, facing, and turning. Vertical lathe machines (VTL) securely hold a workpiece utilizing gravity to keep the part in place, with minimal clamping required. This results in a more secure setup and enhanced accuracy during machining.

How Do VTL Machines Work

The working principle of a Vertical Lathe (VTL) is based on the fundamental concept of rotational machining, also commonly known as “turning.”

The process begins with securing the workpiece onto a vertical chuck or fixture. Unlike traditional horizontal lathes, VTLs have a vertically oriented spindle housing. The turret, which holds the cutting tool, moves vertically along the machine’s vertical column.

As the workpiece rotates, the vertically positioned cutting tool descends to contact the workpiece’s surface. The cutting tool removes material in a controlled manner, shaping and finishing the workpiece.

Lou-Rich’s Vertical Turning Lathe Service

Lou-Rich currently offers an advanced VTL machine service, utilizing 2 Mazak MEGA TURN 900 VTL machines that excel in heavy-duty cutting of low- to medium-profile workpieces.

Applications of Vertical Lathe Machining

Vertical Turning Lathe Machines have diverse applications spanning numerous industries.

VTLs are ideal for handling large, complex components with precision and efficiency, making them ideal for a variety of industries.

Aerospace: The aerospace sector relies on the precision and efficiency of VTLs for crafting critical components, including landing gear, engine parts, and turbine discs. These machines ensure the utmost accuracy in aerospace manufacturing.

Automotive: VTLs play a crucial role in the automotive industry, where they are used to produce transmission components, engine parts, and braking system components. Their precision ensures the quality and performance of automotive systems.

Energy: In the energy sector, vertical lathes are indispensable for fabricating components essential for wind turbines, nuclear reactors, and more. The high precision of VTL machining guarantees the reliability and safety of energy infrastructure.

Heavy Machinery: The manufacturing of heavy-duty equipment, such as construction machinery, cranes, and mining equipment, benefits significantly from VTL capabilities. These machines handle the demanding machining requirements of large, robust components.

General Manufacturing: VTLs are remarkably versatile and ideal for various general machining applications. They shine in working with large and complex workpieces, offering precision and efficiency across a wide spectrum of manufacturing needs.

Advantages of Vertical Lathe Machining

Vertical Lathe Machining stands out for its numerous advantages in precision manufacturing.

High Precision: VTL machines are renowned for their exceptional accuracy and consistent results. This precision is invaluable for applications demanding tight tolerances, ensuring top-notch quality.

Versatility: Vertical lathes handle a diverse range of workpiece sizes and shapes. This versatility minimizes the need for frequent setups and tool changes, optimizing efficiency.

Efficiency: Vertical machining centers (VTLs) excel in material removal, significantly reducing cycle times and enhancing overall productivity. Their proficiency in removing material efficiently is a significant advantage in machining operations.

Reduced Handling: The vertical orientation of these machines minimizes manual repositioning of heavy workpieces. This enhances operator safety and slashes the chances of errors, making the process smoother.

Cost-Efficient: Vertical lathe machines help save time and money by simplifying machining and reducing the need for extra steps. This allows companies to meet their manufacturing objectives efficiently and economically.

Mazak VTL Turning Centers Explained

Unlock Your Manufacturing Potential with Lou-Rich

Vertical Lathe Machining stands at the forefront of manufacturing innovation. It offers a transformative blend of precision, versatility, and efficiency.

Whether your industry is aerospace, automotive, or energy, embracing this cutting-edge technology is your key to maintaining competitiveness.

At Lou-Rich, our vertical lathe machine service is a partnership for progress. With our advanced MEGA TURN 900 Vertical Turning Centers and an experienced, enthusiastic team dedicated to excellence, we’re ready to take on your most challenging projects and turn them into success stories. Contact us today to learn how we can assist with your next venture.