LOU-RICH SERVICES

Contract Manufacturing. Engineered for Success.

Are you looking for a partner in manufacturing?

Fabrication & Welding

Custom and complex metal fabrication is a core competency at Lou-Rich. Our employee-owners are dedicated to going the extra mile to ensure each bend, each weld, each and every project meets your high expectation. From light gauge sheet metal to heavy plate stainless steel, and virtually everything in between, Lou-Rich welders and fabrication specialists do it right.

Here is an overview of our key equipment and capabilities. There is also a PDF document of our Technical Capabilities at the bottom of this page you can download that has more information. Better yet, get in contact with us and let’s talk about your next project.

Capabilities & Equipment Overview:

- 6000 & 10000 watt Fiber Optic Laser

- Efficiently cuts virtually all gauges of material up to 1” thick

- Automated material handling system for quick turns

- 4000 watt Tube Laser

- Versatile material usage; square or round

- Metal Forming

- 90-ton Brake Press

- 175-ton Brake Press

- 60-ton Mechanical Press

- 300-ton Mechanical Press

- Stamping Equipment

- 110-ton Mechanical Press

- 300-ton Mechanical Press

- AWS Compliant Manual Welding

- MIG Weld

- TIG Weld

- Spot Weld

- Robotic Welders

- Five robotic weld cells for higher volume projects and repeatable weld placement and bead control

Machining Solution

With nearly 50 machining centers, Lou-Rich has a wide range of capabilities to meet the most demanding customer projects. Precision machining of simple turned parts, or large complex multi-axis requirements are all within range of Lou-Rich. Many of our operators have been making great parts for decades, and our customers keep coming back because of our unrelenting commitment to quality.

With nearly 50 machining centers, Lou-Rich has a wide range of capabilities to meet the most demanding customer projects. Precision machining of simple turned parts, or large complex multi-axis requirements are all within range of Lou-Rich. Many of our operators have been making great parts for decades, and our customers keep coming back because of our unrelenting commitment to quality.

Download the PDF of our Technical Capabilities document at the bottom of this page to get even more information than what is listed here. If you want to get a firsthand look at our machining area, reach out and set up a time to come tour Lou-Rich. We think you will like what you see.

Capabilities & Equipment Overview:

- Horizontal Machining

- CNC machines from 400MM to 1250MM

- Flexible Machining Centers (FMC) for quick change, nimble production

- Automated tooling

- Vertical Machining

- VTL Open Capacity: Mazak MEGA TURN 900

- Over 20 Vertical Mills

- 5-axis Vertical Machining Center with robotic handing

- Multiple machines with automated pallet changers

- Multiple vertical machines from 3-axis to 5-axis

- Turning Equipment

- Swiss Turning machines able to manufacture parts in a single operation

- Multiple Lathe Bar Feed machines set up in a cell

- Multiple Twin Turret Lathes

- Multiple Single Turret Lathes

- Fixture Design and Build

- In-house design and build of all custom fixtures

- Technical Support

- Dedicated programming and maintenance staff for maximum uptime

- Latest in CAD software, technology and tooling

- Mistake proofing program to ensure quality on every part

Painting & Finishing

The Lou-Rich paint team turns out beautiful parts every day from one of our three application booths. The innovative and efficient paint line and 8 stage wash system was designed just for Lou-Rich and installed in 2012. Our customers appreciate the convenience and quality of our powder coat paint system being under that same roof as the rest of our manufacturing.

Our Technical Capabilities document at the bottom of this page can be download and has additional information about our robust paint and finishing. We welcome a chance to run sample parts, or review specifications on new projects. Give us a call and let’s talk.

Capabilities & Equipment Overview:

- Powder Coat Painting

- 8 stage wash system

- Currently working with most leading paint suppliers

- Environmentally friendly system

- Able to color match and work with custom colors

- Finish options ranging from glossy to wrinkle

- Paint line maximum part size of 4’ x 6’ x 10’

- Liquid Paint

- Capable of producing limited liquid paint projects

- Quick change from Powder for efficiency

- Acceptable Materials

- Sheet metal

- Castings

- Aluminum

- Plastic

- Stainless Steel

- Some exotic metals

- Metal Finishing

- State of the art industrial deburring

- Parts washing, cleaning, and drying

- Quality Commitment

- ISO Certified Class 8 Clean Room for testing and research

- 8000 square foot Process Development Lab

- Hirox Digital Microscope capable of 3200x magnification

Assembly Solutions

As Lou-Rich continues to grow, our customers continue to bring us additional challenges, with assembly projects being one of the fastest growing areas of our business. Not only can we manufacture, machine and paint parts, we can also complete sub-assemblies or even finished goods assemblies.

Every assembly project is different, and our team accepts the challenge of efficiently putting together a project. If you have need for something manufactured and assembled, we should review it together. Download the Technical Capabilities PDF at the bottom of the page to learn more.

Capabilities & Equipment Overview:

- Assembly Cells

- Custom design work cells created for each project

- Leverage Lean principles to maximize product flow

- Well trained employee-owners are always on the look-out for improved systems and ideas

- Assembly Projects

- Electro-mechanical

- Weldment Sub-Assemblies

- Manufactured and purchased component projects

- Finished Goods with Inventory Warehousing and Management

- Quality Management

- Dedicated 35,000 square foot facility

- Operated under our ISO 9001:2015 Quality Management System

- Custom and pneumatic tools to ensure proper fit every time

Complex Manufacturing

Back in 1972 Lou-Rich started as a tool & die shop, and over time as our customers’ requests became more complex, so did our capabilities. Today we thrive on building things that other contract manufacturing companies shy away from. We talk the language of engineers because so many of us are engineers. But even more important than that, Lou-Rich is chock full of problem solvers.

Here are a few things that make Lou-Rich highly capable of taking on very complex and challenging projects. The Technical Capabilities document that can be downloaded at the bottom of this page will provide even more information, but the best way to find out if Lou-Rich is the right source for your next project is to reach out and strike up a conversation.

- Design for Manufacturability

- Part of our Design Review Process is to identify potential areas of improvement

- Actively seek to drive out cost through material utilization, reduced lead times, and design changes

- Cost savings are passed on to our customers and the majority of our complex projects will see cost downs over time

- Process Control

- ISO 9001:2015 Standard achieved in March 2018, with original ISO Certification in 1998

- Well documented Engineering Change process to ensure products are always produced to the current revision

- Process Maps and other Lean tools are applied

- Detailed Work Instruction are created as a guide for correct manufacturing procedures

- Costed Bill of Materials (CBOM) is generated during the quote stage to help identify largest cost drivers, areas of potential improvement, and to document every detail required to effectively produce the needed parts

- Project Management

- One of six Quality Technicians is assigned to every complex project

- On-site Stratasys 3D FDM printer for rapid creation of parts as needed

- In-house fixture design and build eliminates any possible outside errors and reduces lead times

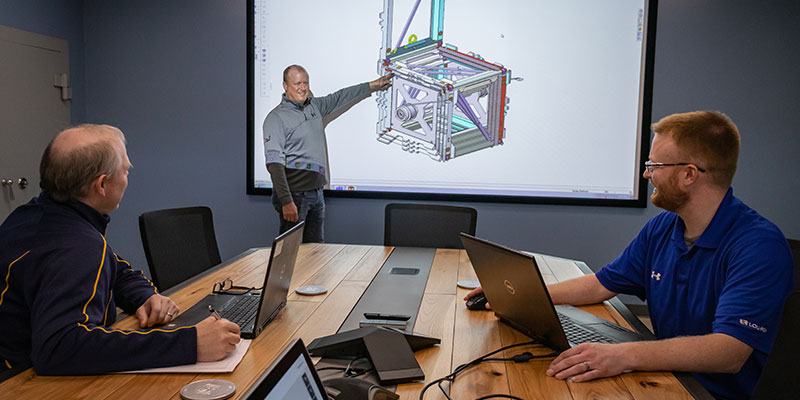

Engineering

Our Program Managers and Project Engineers are focused on successful implementation and on-going production of each of our projects. More than 20 highly skilled engineering and support personnel work closely with all other areas of the business to guide each project from quote to completion.

Talk to someone on our Engineering staff to learn more about how we manage customer projects or download the PDF on our Technical Capabilities at the bottom of the page.

Capabilities & Equipment Overview:

- Project Management

- Project charters define scope of work, key milestones, identify resources and project team members

- Scheduled status reports track project performance and timelines

- One client contact point for easy communication throughout the life of the project

- Product Design

- Complete product engineering documentation and specification

- Product design reviews continuously track requirements throughout the life of the design process.

- All processes and documentation managed under ISO 9001:2015

- Concept development and strong client collaboration

- Manufacturing Process Development

- Strict methodology to calculate, document, and implement the correct manufacturing process

- Best Practice Manufacturing is followed from the start of project planning, into product design, and throughout the product life cycle

- Engineering works closely with production to identify continuous improvement targets that lead to overall project improvements

- Design for Manufacturability mindset with ideas that lead to improved quality, reduced price and shorter production times

Our Commitment to Quality

Your Satisfaction is Our Goal

We are committed to providing quality products and services that consistently meet your expectations. We continually monitor the effectiveness of our quality system and focus our resources on continuous improvement to attain our quality objectives and meet our customer satisfaction goals.

Whether we are developing new products, launching production, deploying people, or delivering shipments, we take every measure to bring the best products to market, faster, and with greater value for you.

ISO 9001:2015 Quality Management System

This framework for our quality management system was developed by our cross-functional team. It is incorporated throughout all of our processes, audited annually by DQS and monitored by internal audits and performance measurables. We provide significant competitive advantages in the global marketplace via our emphasis on high quality, advanced technologies, and innovative solutions.

Quality Assurance

Multiple CMM equipment in climate-controlled setting

Production Part Approval Process(PPAP)

Gage Calibration Program

Internal Auditing

Certificates of Compliance

RoHS & REACH

Utilizing Niton XRF Analyzer

Metrology Equipment

Electronic and mechanical hand-held measurement devices

Monitor Critical To Quality Dimensions (CTQs)

Process Audits

Inspection: First Article, Receiving, First Piece, In-Process

Functional Parts Testing

Trend Analysis for Key Business Measurables

Looking For More?

Visit our YouTube channel to view the following capabilities: Engineering for manufacturability, precision machining, powder coat and liquid painting, fabrication & welding, assembly, sourcing, fixture design/build, and inventory management.