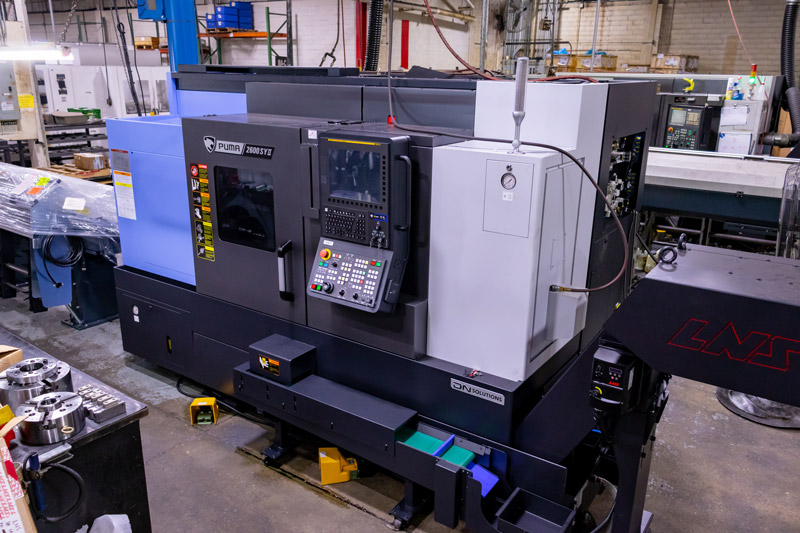

We recently added a new lathe to our Lou-Rich Front Street facility. The new Doosan Puma 2600SY II is a twin spindle, single turret lathe and has a 10-inch main and an 8-inch sub. It offers us more opportunity to automate larger diameter parts and will allow us to streamline our setups.

The new lathe has live tooling, which gives it milling capabilities. It also includes a 6ft automatic bar feeder and Hainbuch quick change collet chucks. Both of these features will allow us to further automate processes. The new lathe is taking the position of an existing piece of equipment and will be placed near our 5 other lathes with automatic bar feeders. This updated setup will allow a single operator to run 2 lathes at a time, requiring only three operators to run all 6 lathes in this machining center.

“I’m excited to consolidate from multiple machines into one machining center. It’ll put out a better, more consistent product without needing additional support,” stated Adam Quimby, Lou-Rich Manufacturing Engineer.

Introducing the DN PUMA 2600SY II from DN Solutions America on Vimeo.

Equipment Specifications

| Capacity | |

| Main Spindle Std Chuck | 10’’ |

| Main Spindle Max Chuck | 10’’ |

| Max Turn Length | 29.9’’ |

| Max Turn Diameter | 14.8’’ |

| Bar Capacity | 3.2’’ |

| Travels | |

| Guideway Type | Box way |

| X Axis Rapid Traverse | 1,181 ipm |

| Z Axis Rapid Traverse | 1,181 ipm |

| Y Axis Rapid Traverse | 394 ipm |

| Main Spindle | |

| Main Spindle Power | 30 hp |

| Spindle RPM | 4,000 RPM |