Lou-Rich’s standard for quality is centered on delivering consistent value, superior products and peace of mind from the first concept through the final production stage. When precision matters and tight turnarounds are the norm, our 4-step quality assurance process is specifically designed to ensure the reliability, repeatability and consistency our customers deserve.

STEP 1: Invest in High-Precision Tools

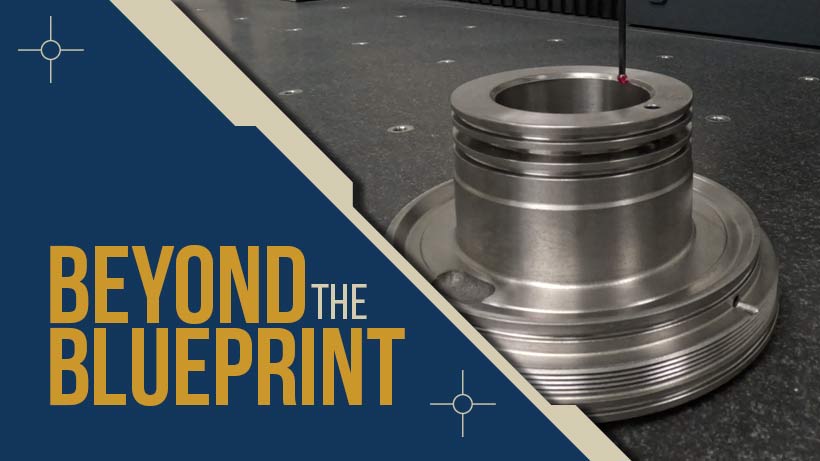

To achieve high-quality results, manufacturers need the right high-precision tools. We leverage six Zeiss coordinate measuring machines (CMMs) across four departments and maintain over 4,500 calibrated gauges. Every new part or print revision we produce goes through a detailed review to determine the right inspection strategy per product, whether by using existing equipment, designing custom gauging or sourcing specialized tools. We invest in high-precision metrology from the start to deliver accuracy.

STEP 2: Earn and Maintain Certifications

Certifications are a key part of our quality assurance strategy. We have maintained our ISO 9001 certification since 1998 and upgraded to the latest ISO standards (ISO 9001:2015) in 2018. For our customers, it ensures every product we deliver meets rigorous quality expectations, every time.

STEP 3: Be FAIR with Our Customers

For each part, we work with the customer to develop a First Article Inspection Report (FAIR) that defines expectations and requirements of the final product.

While every part starts with a First Piece Inspection and receives regular checks throughout the production run, we respect our customers’ unique and proprietary specifications.

FAIRs range from basic to intricate automotive-style Production Part Approval Processes (PPAP) that include

- Process flow

- Failure mode effects analysis

- Control plans

- Inspection checklists

- Capability analysis

- Gauge, Repeatability and Reproducibility studies

If a customer is unclear on specifications, we use our 50+ years of expertise in design for manufacturability to optimize production based on the complexity of a part.

STEP 4: Empower Employees through Ownership

As an employee-owned company, every Lou-Rich team member has a critical stake and responsibility in the outcome of each customer’s product. We’re all vital links in the value chain. It is a responsibility we have to our customer and each other as peer employee-owners. Every Lou-Rich employees’ reputation and livelihood is on the line when a product leaves our building. That is a driving force behind and the important final step in our quality control process. Ultimately, our customers’ success drives our success. Contact our team today so we can accomplish your goals, together: https://lou-rich.com/contact/.