CNC technology makes complex machining and repeatable high quality easier to achieve. At Lou-Rich, we pre-program cutting sequences so repeat orders move through production quickly. In many cases, because of the ways we standardize our processes on our 43 CNC machining centers, we often can start cutting parts the same day we receive a customer’s order. Additionally, because of our expertise in designing parts for manufacturability, we help customers optimize their designs so their parts cost less to produce. We excel at helping customers save money without compromising functionality or quality.

A world of machining

To achieve those results, we use our wide range of CNC machine tool technology in tandem with our 100-plus combined years of CNC programming/engineering experience. Our horizontal mill machining centers range from 1,200 mm (47.2 in) down to 400 mm (15.7 in) machines, and our vertical machining centers can handle workpieces up to 84 x 40 inches. One of the 4 Swiss-style lathes we have handles bar stock up to 2 inches and uses a collet instead of a guide bushing, in a hybrid design that features the best of two machining worlds. Our standard chuck lathes can accommodate up to a 35-inch diameter workpiece, and our high production bar-feed lathes can handle up to 3-inch diameter material. Most of our turning centers have live tool milling capabilities.

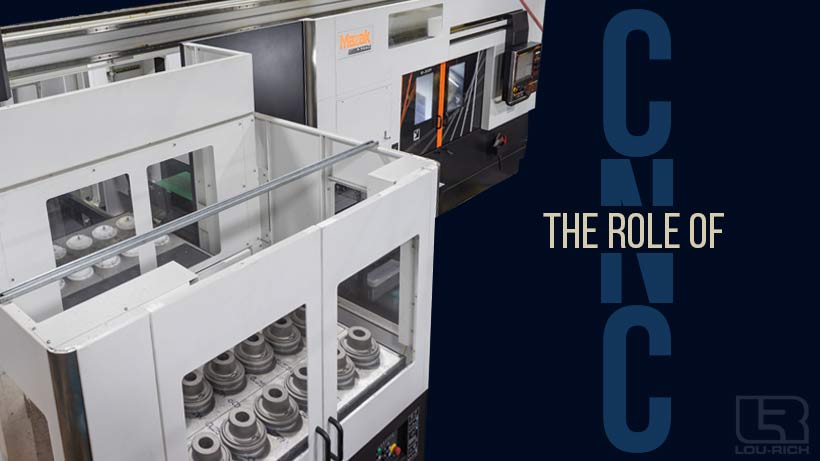

For the ultimate in versatility and productivity, we also own four multi-machine cells based on horizontal machining centers in sizes from 400 mm to 800 mm. The jobs we run in these cells require virtually no setup time once our programming group standardizes each recurring job. Our operators can run multiple orders at the same time by simply entering a part number and quantity, and fixturing and tooling are already onboard the machine tools.

Fixturing expertise

To take full advantage of our CNC technology, we design and produce our own fixturing in house. Not only does this help reduce overall production costs – which puts money back in our customers’ pockets – but it enables us to plan and customize our own process, which increases part accuracy. We also use tombstone and trunnion workholding with in-house modular designs, fitted with the same bolt/pin patterns we use consistently throughout the shop to produce large overall batches of parts. This also helps accommodate the life of parts, from prototype to high production to service or end of life.

Medium volume in small batches

For us, a large batch may run multiple thousands of parts in a year, fulfilled in orders of 25 to 1000’s of parts apiece. This way, our customers have the option to keep their own CNC equipment busy running high-volume parts while we take care of their need for tight tolerances on medium-sized runs. Because we have set up our facility for efficiency and productivity, we can run hundreds of different part numbers without time-consuming changeovers and reprogramming.

Time and quality are money

We constantly move in and out of many jobs, so setup takes away production time that is too valuable to spend on anything other than cutting. CNC technology helps us follow our strategy of reducing setup time and maximizing production-line output. To ensure that we cut parts that truly meet our customers’ specifications, our equipment features built-in probing, which enables us to maintain tight tolerances on complex parts.

CNC technology, Lou-Rich results

For every customer and on every job, we focus on leveraging our CNC technology to fulfill every order quickly and meet every specification precisely. When your job needs tight tolerances on complex machining, Lou-Rich has the talent, experience and equipment to produce what you need when you need it.