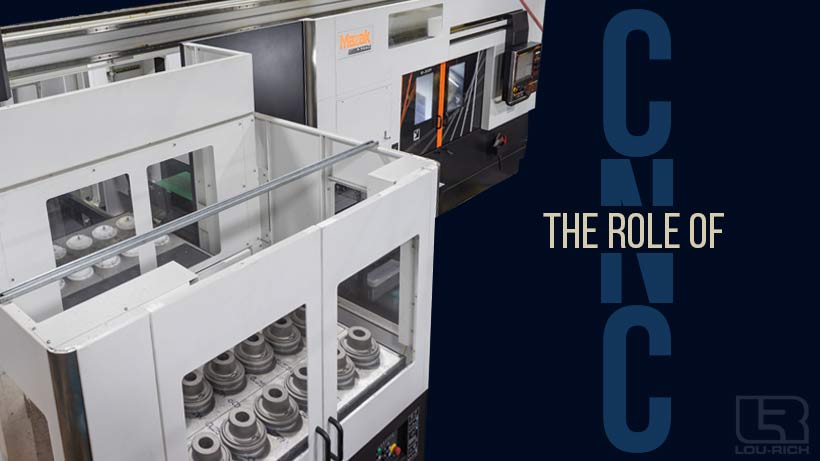

Mazak Multiplex Makes Quick Work

In 2019, like in most recent years, we added several pieces of new equipment to help serve our customers changing needs, increase manufacturing capacity and drive operational efficiencies. One of the big additions we made is the Mazak Multiplex W-300Y Machining Center.

Operational since mid-summer 2019 the Multiplex was purchased in response to additional customer demand. Earlier in the year a long-time customer that is one of the largest agricultural equipment manufactures in the world, awarded Lou-Rich a couple of sizeable projects, making the need for additional machining equipment necessary. “With twin spindles, twin turrets with live tooling and Y axis able to operate different machining sequences when needed, along with the robotic gantry loader, the Multiplex really gives us great overall performance” states Manufacturing Engineer Karl Eggum.

Eggum goes on to say that transferring a current project from a more traditional machining center to the Multiplex improved throughput from 18 parts per hour, to 24 parts per hour. In addition, there is only one part number that needs an additional operation to be completed. Otherwise all parts are machined complete in the Multiplex.

The Multiplex is so efficient that even after taking on new projects and transferring one existing part, the current overall machine capacity is only at about 50%. Eggum says, virtually any part inside the machine envelope of 17 inches in diameter and 13 inches in length could be a good fit. Lou-Rich General Manager Shawn Cheesman added, “The Mazak Multiplex is another good example of our commitment to capital investment that helps our customers be more competitive in the markets they serve.” Over the past several years Lou-Rich has averaged close to $3M in capital equipment investment, with a focus on automation and robotics. Cheesman added, “We enjoy showing off our manufacturing capabilities, and would welcome any request for a full tour of the Lou-Rich facility.”