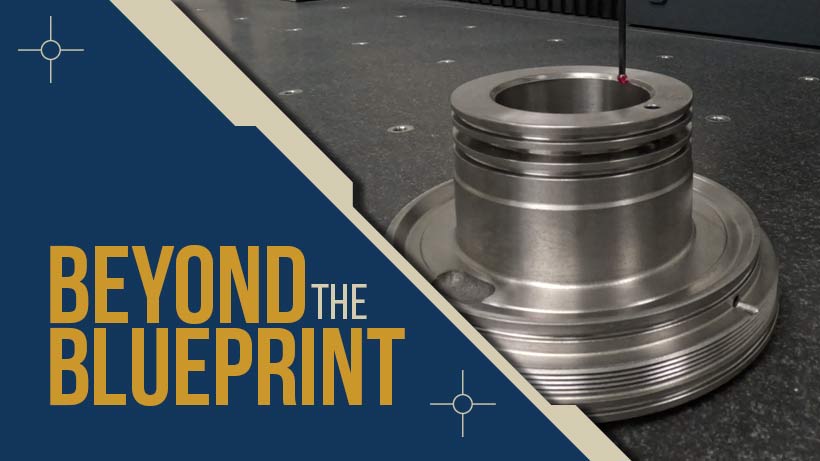

“Turning” Out to be a Special Upgrade

Equipment upgrades happen all the time, in virtually every manufacturing business. But every once in awhile that upgrade is special. In March 2020 Lou-Rich took delivery of a new Doosan Twin Turret Lathe that is “turning” out to be just that – special.

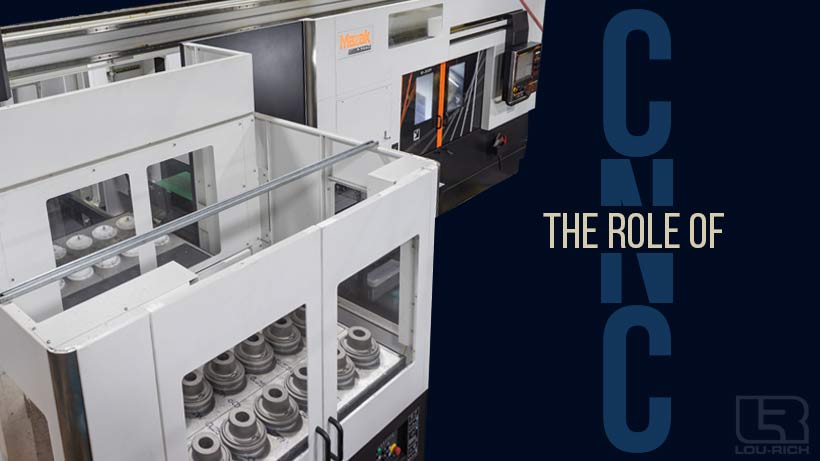

Lou-Rich has seen more and more requests for projects that were challenging for the existing single turret lathes and decided in late 2019, that an upgrade in this area would be part of the equipment investment for 2020. The high-speed turrets index time and rapid traverse rates minimize non-cutting time and maximize efficiencies. “We set up an existing part in the new lathe and because it has twin turrets with main and sub, it dramatically cut down the cycle times” states Karl Eggum, Manufacturing Engineer. “We went from running 30 parts an hour to running 45 parts an hour on the new equipment; and I think we can make improvements on that”.

There is live tooling on both turrets, and both have a y axis, meaning there is a total of 9 axis. This means an incredibly wide range of complex parts can be set up and run very efficiently.

The operators appreciate the 6-foot bar feeder, so there is no manual loading and unloading of parts. This leads to a huge reduction in machine set-up and changeover, and an overall reduction in lead times.

Lee Guldbrandson, Business Development & Engineering Manager added, “This type of equipment helps us be nimble and respond quickly to changing customer needs. Our focus has always been and continues to be getting each of customers the highest quality parts, when they need them”.

This incredible piece of equipment is loaded with a long list of features that makes it unique and yes, even special. With a current capacity of about 50%, there are more new projects the Doosan is ready to take on.