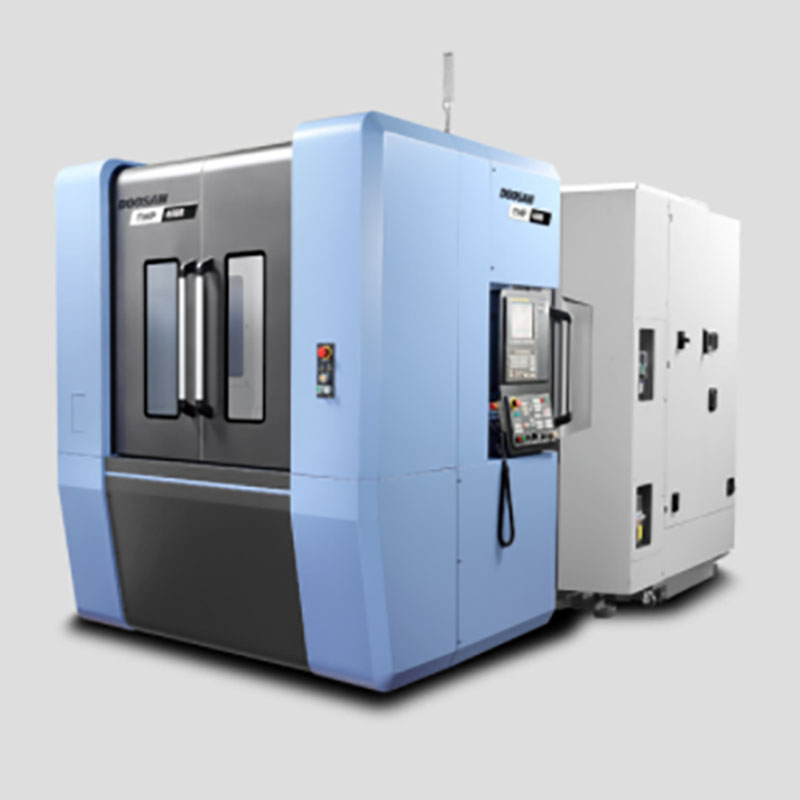

Doosan Machining Centers Doing Double Duty

What do you do with a 20-year-old CNC machine that has been modified and has more than 40,000 cut hours on it? Send it into retirement and replace it with something new of course. Lou-Rich has a significant budget each year for equipment upgrades, replacements and new technology. While much of that budget is often focused on robotics or automation, sometimes workhorse machining equipment is needed, and in this case, we doubled the order.

Lou-Rich took delivery of two new Doosan NHP 4000 horizontal machining centers in August, and we couldn’t be more pleased to add them to the nearly 50 other CNC machines. With a pallet size of 400mm and a speedy spindle rate of 15,000 RPM, these two will make quick work of many different types of projects.

“With a full 4th axis and configured with the ability to change out 60 tools automatically, these two new Doosan’s help us greatly reduce set-up times and change over quickly to help meet shifting customer demands”, says Doug Olson, Production Manager. “Some production efficiencies are also gained”, Olson offered, “but the big win is the increased nimbleness of these centers”. This size of machine offers versatility on the kinds of mid-sized cast and billet parts Lou-Rich runs so much of for our customers. Weighing in at well over 21,000 pounds each, these new machining centers are built for heavy use and quality output. Welcome aboard to the newest members of the Lou-Rich equipment lineup.